Respiratory protective equipment (RPE) is a type of personal protective equipment that filters out contaminants and provides clean air to the wearer. This type of personal protection is designed to protect against fumes and hazardous chemicals that can be found in modern work environments such as factories with heavy machinery. This blog post will discuss different types of respirators and a respiratory selection guide for protecting your workers.

Table of Contents

Types of Respirators

Worksafe QLD classifies respirators into two main types based on the air source: Air purifying respirators and Supplied-air respirators.

Air purifying respirators

Air purifying respirators are designed to protect the wearer by using a filter that removes impurities from air breathed in. They can be either disposable or reusable, and come with two types of functionality: powered or non-powered. Powered models use a fan for an extra layer of protection against harmful substances while non-powered ones rely on users' breathing alone to draw air through the filters.

Disposable Particulate Respirators

Disposable particulate respirators are designed for protection against low concentrations of dust, mists, pollen, animal dust etc.

Advantages: Lightweight, disposable, relatively comfortable, and inexpensive.

Limitations: Minimal protection due to poor sealing properties. They cannot be used by personnel with facial hair which comes between the respirator and the skin.

Re-Usable Half Mask Respirators

Air purifying half masks have a rubber face sealing part which fits over the nose and under the chin. Exchangeable cartridges and filters are designed to provide protection against different types of air contaminants.

Advantages: Relatively lightweight and offer good protection against many contaminants.

Limitations: Use is limited by the type and capacity of the filters – neither can be used in areas with high concentrations of contaminants or in oxygen-deficient atmospheres. Breathing may become more difficult because of additional effort is needed to breathe through the filters. Eye protection is not provided. Although the proper and tight fitting is essential, many factors may affect mask tightness.

Re-Usable Full Face Mask Respirators

Air purifying full face masks work on the same principle as the half-mask respirators described above. The facepiece extends protection around the entire face, covering the eyes, nose, chin and mouth.

Advantages: Full face respirators are used where a higher level of respiratory protection is needed or where eye and face protection is required.

Limitations: Full face masks are heavier than half-masks and often less comfortable for the wearer. Cannot be used for all types of air contaminants and are limited by the type and capacity of the filters and cartridges used. They cannot be used in oxygen-deficient atmospheres. Breathing may become more difficult because of additional effort is needed to breath through the filters.

PAPR – Powered Air Purifying Respirators

The most advanced group of personal protective equipment provides high level of protection even for long lasting applications. Battery powered portable fan unit which drives the air through a particulate or chemical filter and blows it to the headtop. Full and half mask are available as well as wide variety of hoods and helmets.

Advantages: Major advantages are derived from the positive pressure provided by the fan forcing air into the headtop – hood or helmet. This eliminates difficulty in breathing provided by the negative pressure respirators and reduces the importance of a precise facial fit.

Limitations: Higher purchase price and maintenance. Use is limited by the life time of the battery and fan. Can not be used in oxygen deficiency environments.

Supplied-air respirators

Supplied-air respirators are a type of respiratory protection which provide clean air from an independent source that can be either the compressed air cylinder or compressor. This helps in preventing breathing contaminants, such as hazardous gases and chemicals found at construction sites.

Airline Respirators

These respirators provide clean, fresh air to the user from a stationary source such as a compressor or compressed air cylinder. Full face mask and half mask are available as well as wide variety of hoods and helmets.

Advantages: Airline respirators may be used for long periods and provide a high degree of protection from a variety of air contaminants. They provide minimal breathing resistance and discomfort, are light weight and are available at moderate initial cost and low operating costs.

Limitations: Unexpected loss of the air source terminates all protection to the user. Air must be delivered to the mask or hood through a hose which can be difficult to handle and may easily tangle or crimp. These respirators can be used for protection from the most of all air contaminants.

Self-contained breathing apparatus (SCBA)

SCBAs provide the user with clean air from a high pressure cylinder carried on the wearer‘s back. They are equipped with a full face piece and are operated in the pressure demand mode. SCBAs provide the maximum degree of protection available from airborne contaminants.

Advantages: Users carry their air supply with them allowing comparatively free movement over an unlimited area.

Limitations: SCBA units are expensive to purchase and maintain; require the wearer to carry heavy equipment on his back, and provide no more than 40 minutes of continuous use. Personnel with facial hair which comes between the respirator sealing surface and the wearer‘s face cannot use SCBA equipment.

Selecting the right respirators

Choosing the right respirator for your work can be a difficult task. For efficient respiratory protection, it's critical to choose the correct RPE for your work. According to AS/NZS 1715:2009.

Identify which contaminants are present in your work environment

In situations where there are particulate hazards, such as dusts in a factory or sawmill, you will likely wear a filter air purifying respirator. In instances that involve the inhalation of vapors (say from solvents), you may need to equip yourself with other gear like vapor cartridges and/or combinations of both depending on the hazard. In any kind of workspace where oxygen is lacking and/or hydrogen sulfide gas (H2S) present to breathe, it may require additional equipment like a supplied air system to keep workers going without respiratory illness occurring due to their work conditions.

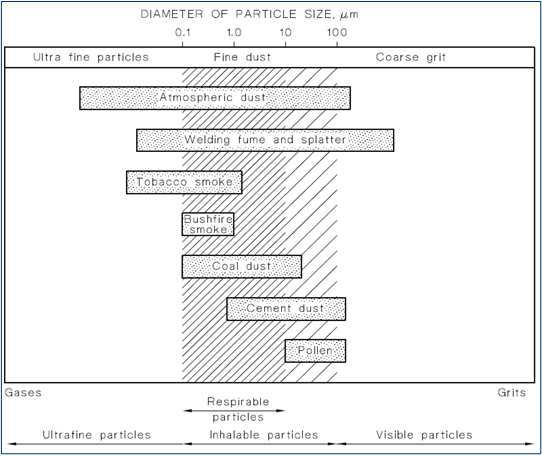

Australian Standard AS/NZS 1715:2009 classifies contaminated air into the following types:

Particulates

Dusts/Fibres

Solid particles generated by mechanical means such as crushing, cutting and sanding.

Examples: calcium carbonate, cement (silica) dust, sulphur, glass-wool, coal, clay, cellulose, cotton dust, flour, ferrous metals (steel, stainless steel, cast iron), wood dust and asbestos.

Mists

Airborne droplets of liquid suspended in air. They are usually formed by condensation of vapour back to a liquid state or breaking up as a liquid into a dispersed state such as splashing, spraying, or atomising.

Examples: oil mist produced during cutting and grinding operations, acid mists from electroplating, acid and alkali mists from pickling operations, the condensation of water vapour to form a fog and paint mist.

Fumes

Fine particles, usually less than 1.0μm in diameter, formed from a volatilised solid that has condensed in cool air. In most cases the hot vapour reacts with air to form an oxide. Fume is often associated with molten metals especially in processes such as welding.

Examples: welding, soldering, brazing and bushfire smoke.

Vapors and gases

Gases

Gases are formless fluids that expand to occupy the space or enclosure in which they are confined.

Examples: nitrogen, oxygen and carbon dioxide and carbon monoxide.

Vapours

Vapour is the gaseous form of a substance which is normally in the solid or liquid state at room temperature and pressure.

Examples: methylene chloride, toluene and mineral spirits.

Determine level of protection needed

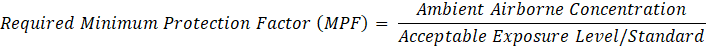

The Required Minimum Protection Factor (MPF), as defined by Australian Standard NZ-1715:2009, is essentially a numerical value that contributes towards reducing the wearer's exposure below their accepted levels. MPF ranges from 10 to 100+. The equation of MPF as below:

Suitable respiratory protective equipment – particulates

|

Required Minimum Protection Factor

|

Mechanically Generated Particulates

|

Thermally Generated Particulates

|

|

Up to 10

|

- P1, P2 or P3 filter half facepiece replaceable filter

- P1 or P2 disposable facepiece

- Powered Air-Purifying Respirator (PAPR)-P1 Filter in PAPR with head covering or facepiece

|

- P2 or P3 filter half facepiece replaceable filter

- P2 disposable facepiece

|

|

Up to 50

|

- P2 filter in a full facepiece

- PAPR-P2 filter in PAPR with any head covering or full facepiece

- PAPR-P3 filter in PAPR with any head covering

- Half facepiece with positive pressure demand or continuous flow air-line

- Half facepiece – air-hose with electronic blower

|

- P2 filter in a full facepiece

- PAPR-P2 filter in PAPR with any head covering or full facepiece

- PAPR-P3 filter in PAPR with any head covering

- Half facepiece with positive pressure demand or continuous flow air-line

- Half facepiece – air-hose with electronic blower

|

|

Up to 100

|

- P3 filter in full facepiece

- Full facepiece air-hose (hose mask) natural breathing type

|

- P3 filter in full facepiece

- Full facepiece air-hose (hose mask) natural breathing type

|

|

100+

|

- PAPR-P3 filter in PAPR with full facepiece or head covering and blouse

- Head covering air-hose with electrical blower

- Head covering air-line respirator – continuous flow

- Full facepiece air-line respirator – positive pressure demand or continuous flow modes

- Full facepiece air-hose with electric blower

|

- PAPR-P3 filter in PAPR with full facepiece or head covering and blouse

- Head covering air-hose with electrical blower

- Head covering air-line respirator – continuous flow

- Full facepiece air-line respirator – positive pressure demand or continuous flow modes

- Full facepiece air-hose with electric blower

|

Suitable respiratory protective equipment – gas and vapours

|

Required Minimum Protection Factor

|

Maximum gas/vapour concentration present in air ppm (by volume)

|

Suitable Respirator Protective Equipment

|

|

Up to 10

|

1 000

|

- Class AUS, 1,2 or 3 filter with half facepiece replaceable filter or disposable facepiece

- Class PAPR-AUS, PAPR-1 or PAPR-2 filters in a PAPR with any head covering or facepiece

|

|

Up to 50

|

1 000

|

- Class AUS or Class 1 filter with full facepiece

|

|

Up to 50

|

5 000

|

- Half facepiece air-line respirator with positive pressure demand – or continuous flow

- Half facepiece air-hose with electric blower

|

|

Up to 100

|

5 000

|

- Class 2 filter with full facepiece

- Class PAPR-2 filters, with full facepiece PAPR

|

|

Up to 100

|

10 000

|

- Class 3 filter with full facepiece

- Full facepiece air-line respirator – negative pressure demand

- SCBA negative pressure demand

- Full facepiece air-hose (hose mask) natural breathing type

|

|

100+

|

|

- Full facepiece, head covering or air-supplied suit with air-line respirator – positive pressure demand or continuous-flow

- SCBA positive pressure demand

- Full facepiece air-hose with electric blower

|

Select the right type of filter

AS/NZS 1716:2012 – Respiratory Protective Devices details the types of particulate and gas filters and their capacity that are available in Australia.

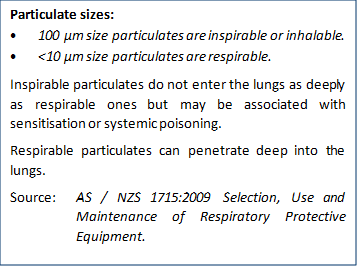

Particulate filters and cartridge

Particulate filters are designed to protect against solid and liquid particles as well as micro-organisms. However, particulates do not offer protection from gases or vapors that can be harmful such as solvents. Particulate filters are classified into categories P1 (lowest level of protection), P2 (moderate) or P3(highest).

|

Class of Particulate Filter

|

Type of Particulate

|

Particulate Size

|

Availability

|

Efficiency

|

Application

|

|

P1

|

Mechanically generated particulates, e.g. silica and chrysotile

|

Up to 100 µm

|

Powered, replaceable, and disposable

|

80% (particles to 1μm

P1 micron = 0.001mm size)

|

Dust

|

|

P2

|

Mechanically and thermally generated particulates, e.g. metal fumes

|

< 10 µm

|

Powered, replaceable, and disposable

|

94% (particles to 0.3μm

P2 micron = 0.0003mm size)

|

Toxic dusts including

asbestos, welding fumes

|

|

P3

|

All particulates including highly toxic materials, e.g. beryllium

|

-

|

Powered and replaceable.

NOTE For P3 filter classification, a full-face respirator is required. When a P3 filter is used in a half-face respirator it has a protection factor equivalent to a P2 filter.

|

99.95% (particles to <0.3μm

micron = less than

0.0003mm size)

|

Toxic dusts including

asbestos, welding fumes,

full face and powered air

performance at P3 only

|

Gas and vapour filters and cartridges

Gas and vapour filters are usually used when there is a gas or vapor hazard in the air. A number of respirator gas filters exist to remove specific gases from the surrounding environment, but not against particulates like dust particles.

For protection from gases and vapours, you need to ensure that your filter is able to absorb the type of gas or vapor it's protecting against. The types of filters, from lowest absorption class AUS all the way up to Class 3, represent their capability of absorbing contamination.

|

|

|

|

|

Low absorption capacity filters

|

|

|

Low to medium absorption capacity filters

|

|

|

Medium absorption capacity filters

|

|

|

High absorption capacity filters

|

***NOTE – Where there is a hazard of both gas/vapours and particulates, both types of filters must be used.

|

Filter Types for Gases and Vapours

|

|

Filter

|

Examples of Contaminants / Uses

|

Cartridge Colour

|

|

Type A – organic vapours

|

Solvents (with boiling point above 65°C)

|

Brown

|

|

Type B AUS or B1 – acid gases

|

Chlorine / sterilization of water, chemical manufacture, hydrogen chloride / chlorinated organic chemical manufacture, steel pickling

|

Grey

|

|

Type B2 and B3 – acid gases and hydrogen cyanide (HCN)

|

Plastics manufacture, gold ore refining, HCN fumigation

|

Grey

|

|

Type E – sulphur dioxide (SO₂)

|

SO₂/casting of metals, bleach manufacture, manufacture of sulphuric acid, fertilizer manufacture, metal cleaning, petroleum refining

|

Yellow

|

|

Type G – agriculture chemicals

|

Low vapour pressure (below 1.3 Pa at 25°C) organic vapours, pesticide spraying, mixing manufacture

|

-

|

|

Type K – Ammonia (NH₃)

|

NH₃/refrigeration, manufacture of fertilizers, explosives, plastics, low boiling point amine/chemical manufacture

|

Green

|

|

Type AX - Low boiling point organic compounds (below 65°C)

|

As specified by the manufacturer, e.g. dimethyl ether, vinyl chloride

|

Brown

|

|

Type NO - Oxides of nitrogen

|

Oxides of nitrogen

|

Blue

|

|

Type Hg – Mercury

|

Metallic mercury/chemical industry, inorganic-mercury compounds

|

Red

|

|

Type MB - Methyl bromide

|

Fumigation

|

-

|

Maxisafe, one of the leading RPE manufacturers in Australia, provides a respiratory filter selection chart as a guide to help you in choosing the right respirators and filters.

Respirator Selection Chart for Maxisafe® filters

Reference

Mining and Quarrying Occupational Health and Safety Committee 2018, Respiratory PPE – Selection and Use Guide, media release, 5 December, Mining and Quarrying Occupational Health and Safety Committee, viewed 27 July 2021, <https://www.maqohsc.sa.gov.au/wp-content/uploads/2017/01/MAQGUI-025-Respiratory-PPE-Selection-and-Use.pdf>

Safe Work Australia 2019, Workplace Exposure Standards For Airborne Contaminants, media release, 16 December, Safe Work Australia, viewed 27 July 2021, <https://www.safeworkaustralia.gov.au/system/files/documents/1912/workplace-exposure-standards-airborne-contaminants.pdf>

Techware Pty Ltd 2020, Maxisafe Respirator Catalogue 2020, Techware Pty Ltd, viewed 27 July 2021, <https://maxisafe.com.au/wp-content/uploads/Maxisafe-Respirator-Catalogue-2020.pdf>